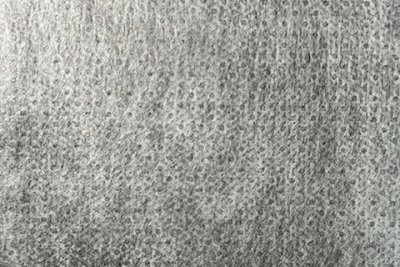

What is Meltblown Nonwoven?

Meltblown nonwoven is a fine-fiber nonwoven fabric made by extruding molten polymers through tiny nozzles and attenuating them with high-speed hot air. This results in a web of ultra-fine fibers with excellent filtration properties. At Yiting, meltblown is primarily used for high-performance filter media in coffee filters,tea pouches , and medical-grade materials.

How is Meltblown Nonwoven Made?

The meltblown process consists of:

Polymer Feeding & Melting– Polymers like polypropylene are melted to a specific viscosity.

Extrusion through Die– The molten polymer is extruded through micro nozzles.

Air Attenuation– High-speed hot air stretches the fibers into micro- and nano-scale diameters.

Web Formation– The fine fibers are deposited onto a conveyor to form a uniform web.

Yiting uses precision-controlled dies and airflow systems to ensure fiber consistency and filtration efficiency.

Material Characteristics & Technical Advantages

Meltblown nonwoven features:

- Extremely fine fiber diameter (1–5 microns)

- Superior filtration efficiency (dust, bacteria, particles)

- Soft, drapable texture

- Electret-treated for enhanced static filtration

- Available in biodegradable versions upon request

Ideal for single-use filters and barrier applications.

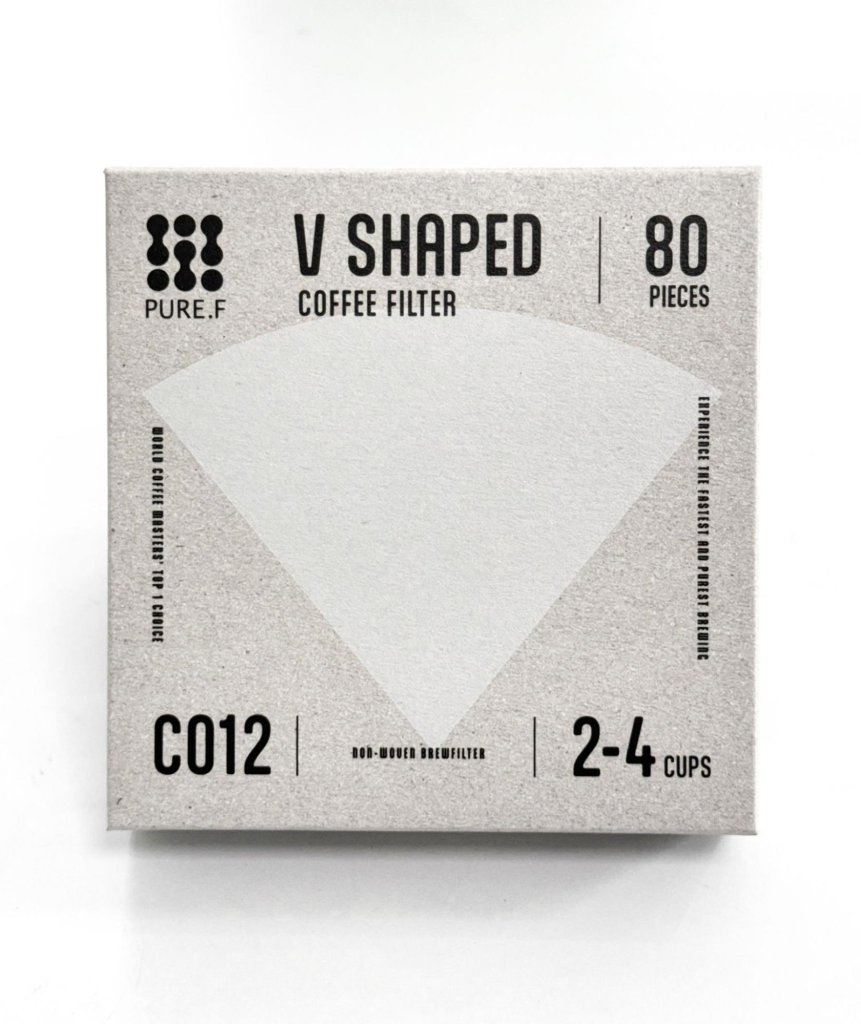

Yiting Product Applications & Examples

Key Yiting products incorporating meltblown nonwoven:

Pure.F Coffee Filter– Multi-layer filtration using meltblown for fine particle retention.

Tea Pouch Materials– Combines meltblown with spunbond or water-jet layers for smooth texture and filtration.

Face Mask Inner Filter Layer– Custom projects available on request.

Customization & Partnership Options

Yiting offers:

- Small-batch sampling for prototyping

- Adjustable basis weight and porosity

- Biodegradable PLA meltblown on request

- OEM/ODM capabilities with food- and medical-grade compliance

We assist customers from concept to commercialization with rapid turnaround.

Proven Track Record & Global Reach

Examples of Yiting’s meltblown partnerships:

- Collaborated with EU partners on food-safe coffee filter development

- Supported Southeast Asian customers with meltblown filter solutions for air and water purification

We ship globally with ISO-certified quality.

FAQ

Q1: What are meltblown nonwoven fabrics used for?

A: Filters (liquids, air), masks, and fine-particle barrier layers.

Q2: Can meltblown be customized for eco-friendly applications?

A: Yes, we offer PLA-based and biodegradable meltblown materials.

Q3: Does Yiting support small-volume development?

A: Absolutely. We support flexible MOQ and formulation testing.